The fully automatic vacuum packaging machine modle PBV works from a flat film reel, forms the bag over a forming shoulder, transfers the empty bag into adapted guiding, shafts, fills the bag, introduces same into the vacuum station and closes the bag after the vacuum process is finished.

The machine conception is based on the modular manufacturing system. The modules of which the machine is composed are the followings:

Vertical packaging machine

For carrying empty bags with the transfer boxes adapted guides.

Carousel-bag transport

Housings with guides adapted for transporting bags to different stations then integrated.

Filling station

To fill the bags.

Vacuum station

To perform the vacuum inside the bags.

Closing station

Within the integrated vacuum system for closing the top of the bag after the vacuum conducted.

Cutting station

Installed below the vacuum station for cutting the top end of the bag.

Taking away belt

For extracting the filled and closed bags to the outside of the machine.

All laminates which are suitable for vacuum bags e.g.

- alu/paper/poly

- alu/polyester/poly

All products suitable for existing dosing systems e.g. powder, granulates.

- Mini. 40x60x150

- Max. 45x85x270

- Volumetric Cup Feeder

- Auger Feeder

- Electronical Weigher

Max. 40 bags/min. depending on product, bag dimensions and dosing system

- Compressed Air: 21 m3/h

- Power Supply: 6 KW at 8 HP 2

- Tension: 220/380 V., 3 Ph., 50 or 60 Cycles.

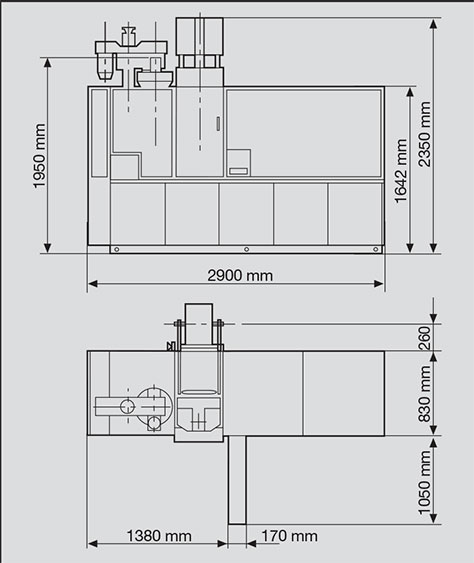

- Weight: Approx. 2000 Kg. net.

- Labellor.

- Fully automatic cartoning system (for cartoning the individual bags).

- Fully automatic bag overwrapping device (for overwrapping the bags individually).

- Válvula