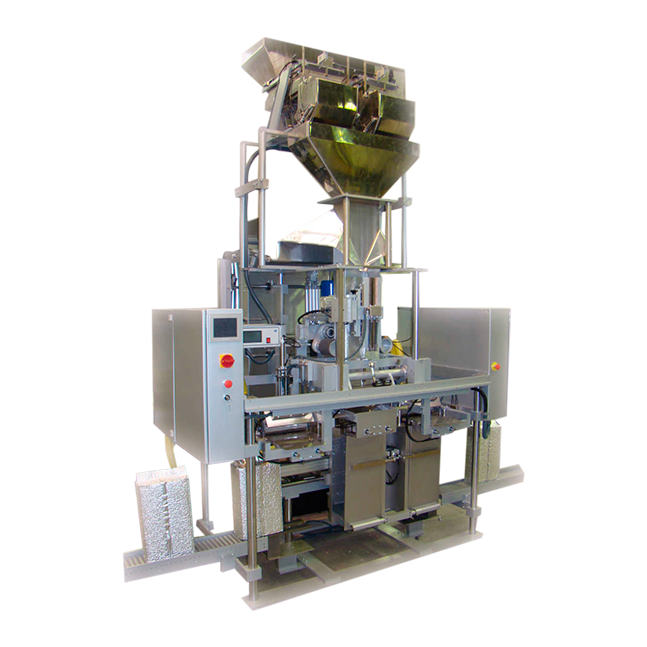

The machine WX-10/V of vertical packing, makes fills and closes the bags starting from a reel made of thermoweldable material through impulse or constrant heat.

To make the vacuum inside the bags , the machine WX-10 at the bottom of the horizontal welder takes a few boxes which besides moving the bag until a vacuum chamber , and properly fit concoct the top of the bag.

Once this first phase and the bag is located below the vacuum chamber , proceed to the extraction of internal air from the bag through a mechanism which enters the inside of the hood and then proceeds to seal and cut excess of the bag. Using this time the packaging , it has made and filled another bag.

It is designed so that any type of dosimeter or weigher can be adapted to it either directy on the machine or laterally carrying out the feeding of the machine through a lift or other transport systems.

In the food trade it can be applied to the sugar, legums, fried potatoes, snacks, pastes, dehydrated salt, sweets, biscuits, dry fruits, cakes, coffee, tea, etc. in the case of dry fruits can even be formats up to 12kg.

In the industrial sector, it is very useful for bricolage parts, accesories, buttons and for all types of parts which can be dosed through the means described above.

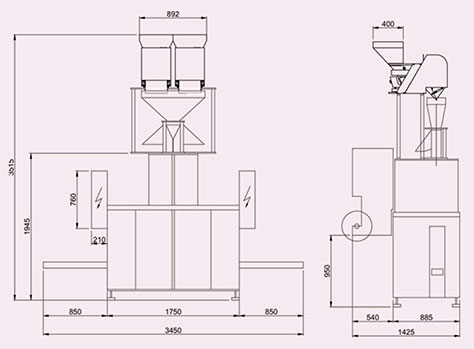

- Width: min. 60 mm. max. 300 mm

- Height: min. 50 mm. max. 600 mm

- To make a change in the bag width it´s necessary to change the maker.

- To change the height, it can be regulated through a device which acts on the transport mechanism.

The speed of the machine is 6 bags/min. for formats of 10kg. In smaller formats the packaging speed increases.

- Compressed air: 19 m3/h . 6 bar

- Electric consumption: 16 A

- Voltage: (depending on the order) 220/380 V. 50 ó 60 Hz.

- Net wight of the basic machine: 2.000 Kg. aprox.

- Reel final stopping.

- Non product non-bag stopping.

- Inert gas injection.

- Intermediate hopper vibrator.

- Powder intake.

- Dosed bag counter.

- Outlet belt for finished bags.

- Sealing and coding unit.

- Valve.