The machine PA-20 is a simple monobloc machine designed for all who were filling the bags manually go to have a machine that makes the whole process automatically.

The machine is designed to take the bags one by one from a storage bag, then it opens and fills them, and finally it closes the bags by constant heat. Once the cycle is completed, the bags come out completely finished by the outlet belt.

Any type of doser may be adopted: an electronic weigher, a volumetric cup feeder, an helicoidal auger filler, or a pieces counter.

In the food processing industry, it can be applied to the packing of sugar, vegetables, fried potatoes, snacks, pastes, packing of sugar, vegetables, fried potatoes, snacks, pastes, dehydrated or wet salt, chocolates, sweets, biscuits, dried fruits, cakes, coffee, tea, etc…

In the industrial sector, it is best used for D.I.Y. parts, bolts and nuts, accessories, buttons and all types of parts in general, which can be proportioned using the means described above or other different means.

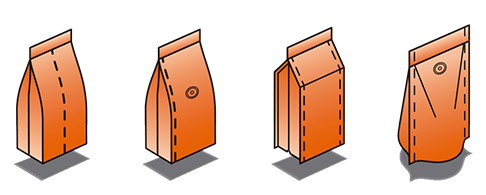

The machine accepts different types of bags and formats. The storage bag can be adjusted easily.

The mechanical speed of the machine is up to 15 cycles / minute. The real production depends on the type of product to be packed, weight and type of doser.

- Bottom overture rammer

- Intermediate hopper vibrator.

- Powder intake.

- Dosed bag counter.

- Outlet belt for finished bags.

- Coding unit.

- Electronic weigher PS/8

- Volumetric cup feeder V-8

- Helicoidal auger filler VS-8

- Compressed Air: 20 m3/h a 6,5 bar constant

- Electric consumption: 10 A

- Voltage (depending on the order): 230 V – 50 Hz.

- Max. production: 15 cycless/min. (according produc)

- Net weight of the basic machine: 500 Kg. aprox.