PBV

DESCRIPTION

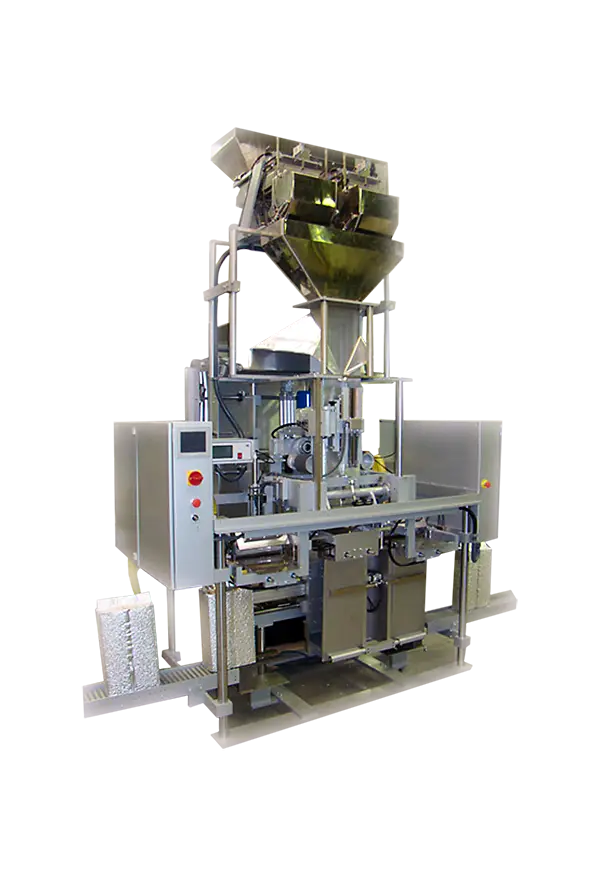

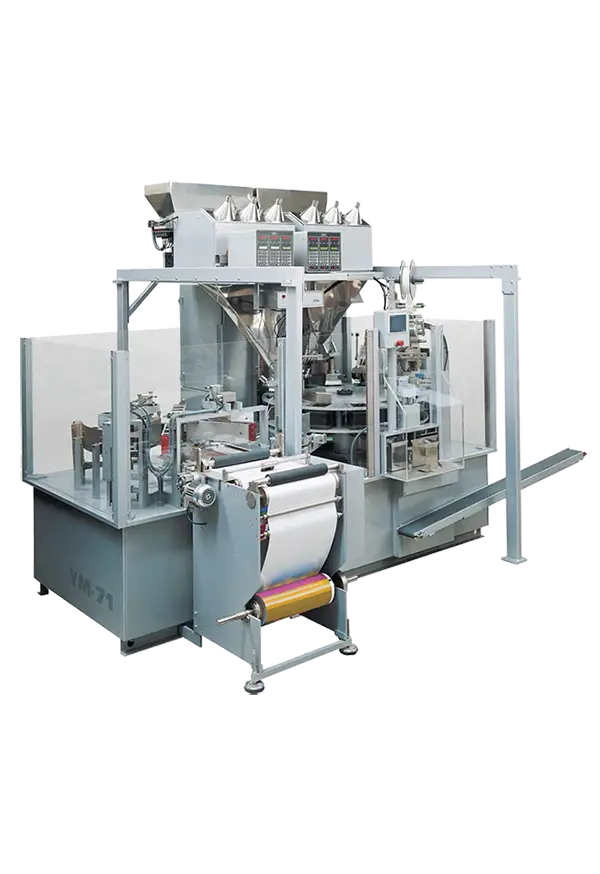

Automatic carousel machine that, starting from a reel, forms, fills, and seals the bag while vacuuming. Especially suitable for vacuum-sealed packages like coffee.

The fully automatic vacuum packaging machine modle PBV works from a flat film reel, forms the bag over a forming shoulder, transfers the empty bag into adapted guiding, shafts, fills the bag, introduces same into the vacuum station and closes the bag after the vacuum process is finished.

The machine conception is based on the modular manufacturing system. The modules of which the machine is composed are the followings:

WRAPPING MATERIALS

All laminates which are suitable for vacuum bags e.g.

PRODUCTS

All products suitable for existing dosing systems e.g. powder, granulates.

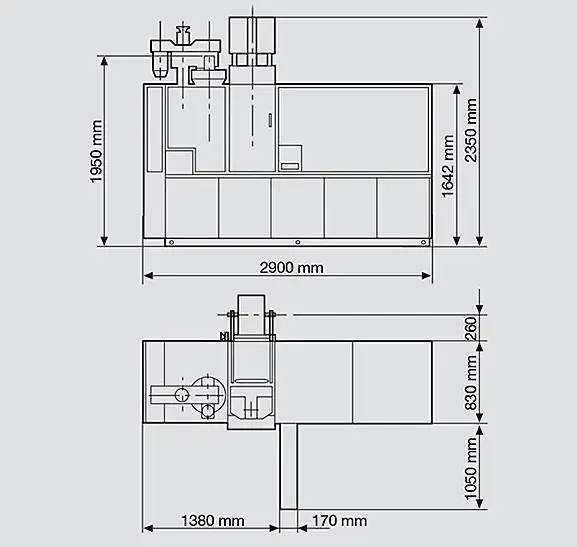

BAG DIMENSIONS

DOSING SYSTEMS

CAPACITY

Max. 40 bags/min. depending on product, bag dimensions and dosing system.

BAG SHAPES

Upright standing block bottom bags with:

ACCESSORIES

READY TO SIMPLIFY YOUR PACKAGING?

Talk to our team and find out how to make your packaging process more profitable.